I. Background

As global demand for efficient supply management increases, traditional methods are often insufficient. The push for high-quality and effective resource management has intensified worldwide. This involves moving from traditional factor-driven models to innovation-driven approaches and integrating new technologies such as big data, the internet, and artificial intelligence deeply into the transportation sector.

II. Intelligent Hardware

Smart General Cabinet

Primarily manages workshop tools, achieving unattended and remote material handling. Operators complete identity verification through configurable modules such as facial recognition, RFID, barcode scanners, and IC cards. Upon authorization, tools can be checked out and returned via voice prompts on a touchscreen. The entire process of check-out and return is recorded for data analysis, traceability, and accountability.

Key Features:

1. Remote Management: Synchronizes device status, location information, and management system data on PC and mobile apps.

2.Customizable Combination: Tailored to different scenarios and material specifications, with customizable cabinet configurations.

3.Data Analysis: Provides multi-dimensional data analysis.

4.Multiple Login Methods: Supports various login methods including barcode scanners, RFID, facial recognition, fingerprint, and passwords.

Smart Keys Cabinet

1. Key Take-Out and Return Management: Field personnel verify identity using user ID, password, facial recognition, etc., and log into the smart storage. The system automatically records user information and usage details. Upon return, the system logs the key return process.

2. External Key Storage Management: Equipped with dedicated management compartments for centralized storage of external keys.

3. Key-Tag Binding: Each key is bound to a tag. When returned to the smart key storage, the key is locked into the storage compartment, and can only be removed when the system unlocks it.

4. Customizable Management: Customizes cabinet structure, core circuits, and software processes according to user requirements.

5. Smart Retrieval: Allows retrieval of keys by maintenance or management personnel through a search function.

6. Key Return Indicator: Features indicators for returned/unreturned status near the return location.

The Smart Keys Cabinet Features:

1. Multiple login methods; unique identification through barcode scanners, RFID, facial recognition, fingerprint, and passwords.

2.Remote control with fault diagnosis and upgrade capabilities.

3.Take-out and return records for statistical analysis.

4.Centralized management replacing traditional methods, achieving unattended distribution.

5.Real-time RFID detection and optimized structural angles for ease of use, with independent tag binding.

Smart Toolbox

The Smart Toolbox is an intelligent terminal device developed with deep understanding of railway tool management. It enables rapid counting of core tools. The toolbox uses industrial-grade embedded components, offering high integration, durability, excellent performance, and reliability. It supports JAVA API development for integration with client backends and compatibility with smart tool management software systems.

Key Features:

1. Utilizes ultra-high-frequency RFID technology for rapid inventory and automatic identification.

2. Equipped with the world’s most powerful RFID chip and classic Android operating system.

3. Real-time tool inventory display on the app, with smart management for tool allocation, procurement, and replenishment.

4. Electronic accounting and reconciliation of tool check-in and check-out data.

5. Quick inventory with the ability to scan 25 tools in just two seconds.

6. Nylon fabric partitions and hanging boards for easy tool access.

7. Metal and aluminum construction for durability, aesthetics, and signal protection.

8. Card system for identity verification and door opening.

9. Features online upgrades and synchronization, making it truly smart.

Smart Charging Cabinet

Functions:

1. Manages the charging of devices.

2. Monitors the devices and it’s batteries status

3. Authenticates and manages user information.

4. Manages check-out and return of charging devices.

5. Statistics and management of the use of charging devices and batteries.

6. Ensures that borrowed devices are not replaced or substituted.

7. Monitors the charging process in real-time.

8. Remote viewing of surveillance footage via network cameras.

9. 24/7 operational capability with facial recognition system.

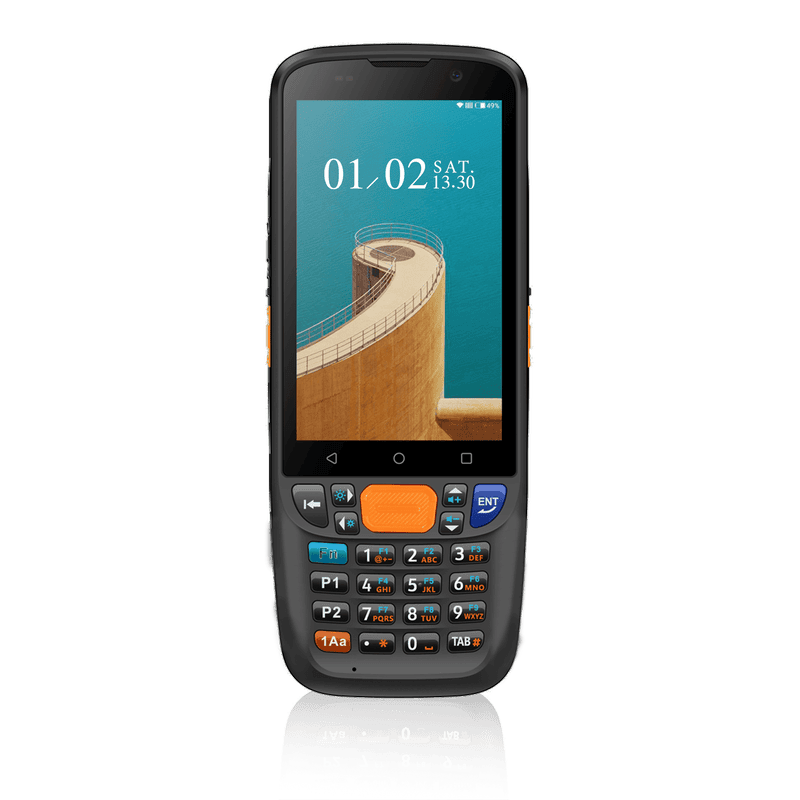

Smart Mobile Computer

Integrates modules such as RFID readers, 1D or 2D barcode readers, temperature sensors, infrared thermal imaging, vibration sensors, facial recognition, positioning modules, voice communication, and wireless communication. It supports data collection, processing, storage, and real-time upload. It can flexibly handle applications including communication, EAM, risk inspections, construction operations, rail freight operations, axle station operations, emergency ticket inspection, product sales & ordering, tool management, and cloud temperature measurement. It supports RFID tags, 1D or 2D barcodes, temperature, vibration, sound, and location checks, with rapid data collection using Bluetooth and WiFi modules.

Intelligent Management System

Material Lean Management Platform

Design Concept:

The material management system adopts IoT technology, combines the idea of lean material management with the material's unique identification code to integrate the data resources originally distributed in various application systems, and realize the full life cycle management and full track management of materials. It has the functions of automatically generating purchase lists, automatically calculating existing values, inventory warning, online management of scrapping processes, etc. It uses mobile terminals and computers to support the processing of real-time information on materials to the maximum extent, gives full play to the collaborative interaction between human and machine, improves material management performance, and enhances the level of lean material management in enterprises.

System advantages and features:

1. Realize the full life cycle and full track management of materials;

2. Realize the specialization, standardization, process, dataization and refinement of enterprise material management;

3. Realize intelligent early warning of material information, material history information tracking, and automatic generation of purchase lists;

4. Improve inventory management accuracy and reduce inventory management costs;

5. Reduce the error rate of human material management;

6. Reduce capital occupation and inventory management investment.

Technological Features

Utilizes "facial recognition technology and QR code + RFID identification", with the material's unique identification code to integrate the data resources originally distributed in various application systems. Achieves full lifecycle and full traceability management of supplies.

Collects, associates, and tracks information on personnel, tools, and materials (fixed assets, high-value interchangeable parts, low-value consumables).

Tool and Material Full Lifecycle Management

The tool management system can realize the functions of tool basic information management, outbound, inbound, calibration, configuration, etc. In addition to being practical when operated alone, the entire tool management system is combined with the smart tool cabinet and guided by the unattended management idea. It uses a variety of means to identify people and individual tools, and combines the company's existing management system to improve the management precision of tools. The system can meet the needs of long-term use in harsh industrial environments and complete the intelligent management of the issuance, recycling and maintenance of tools and materials..

Quantitative Management

Provide consumables and tools packages qualitatively, quantitatively and regularly according to maintenance tasks to reduce waste;

Refine maintenance and improve maintenance procedures and systems;

Damaged replacement parts must be returned to improve maintenance quality;.

Quantitative Distribution

(1) Extend the traditional material management field to the production support link;

(2) Distribute consumables and tools qualitatively, quantitatively and regularly according to the maintenance tasks;

(3) Object-oriented borrowing and returning, outgoing and incoming, simplifying the approval process;

(4) True professional specialization - maintenance workers and delivery workers, with clear division of labor;

(5) Maintenance workers concentrate on carrying out maintenance work and formulating the best maintenance plan;

(6) Delivery workers concentrate on providing the most sophisticated maintenance equipment, maintenance tools in the best condition and consumables delivered on demand;

(7) Maintenance workers can give star ratings to delivery workers' services;